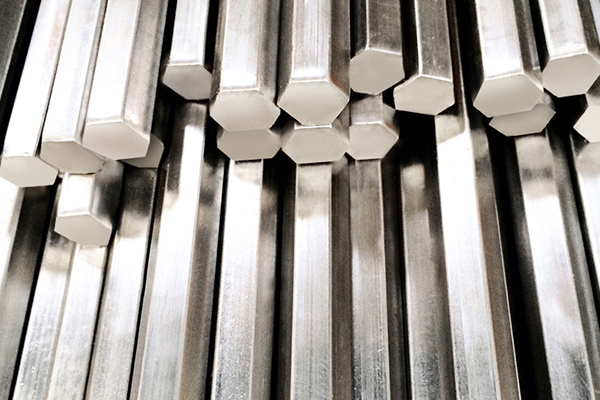

300 series stainless steels are also called as austenitic stainless steels as well as 18-8 chromium-nickel alloys. Containing a lot of chromium, the 300 series stainless steels therefore presents better resistant to rusting than other steels. Noticeably, they are able to keep their strength at higher temperatures; likewise, their ductility can be maintained at lower temperatures. Consequently, 300 series stainless steels are widely applied in many industries. All in all, they are non-magnetic, easy to machining, and difficult to rusting.

| Stainless Steels | Chemical Composition, % | |||||||||

| TYPE | C | Si | Mn | P | S | Ni | Cr | Mo | Cu | other |

| 301 | ≤0.15 | ≤1.0 | ≤2.0 | ≤0.045 | ≤0.030 | 6.00~8.00 | 16.00~18.00 | |||

| 303 | ≤0.15 | ≤1.0 | ≤2.0 | ≤0.200 | ≥0.15 | 8.00~10.00 | 17.00~19.00 | ≤0.60 | ||

| 303Cu | ≤0.15 | ≤1.00 | ≤3.0 | ≤0.200 | ≥0.15 | 8.00~10.00 | 17.00~19.00 | ≤0.60 | 1.5~3.50 | |

| 304 | ≤0.08 | ≤1.00 | ≤2.0 | ≤0.045 | ≤0.030 | 8.00~10.50 | 18.00~20.00 | |||

| 304L | ≤0.03 | ≤1.0 | ≤2.0 | ≤0.045 | ≤0.03 | 9.0~13.0 | 18.00~20.00 | |||

| 316F | ≤0.08 | ≤1.00 | ≤2.00 | ≤0.045 | ≥0.10 | 10.00~14.00 | 16.00~18.00 | 2.00~3.00 | ||

| 316 | ≤0.08 | ≤1.00 | ≤2.00 | ≤0.045 | ≤0.030 | 10.00~14.00 | 16.00~18.00 | 2.00~3.00 | ||

| 316L | ≤0.03 | ≤1.00 | ≤2.0 | ≤0.045 | ≤0.030 | 12.00~15.00 | 16.00~18.00 | |||

| NSSC130M | 0.07~0.12 | ≤1.0 | 9.0~10.0 | ≤0.030 | ≤0.030 | 5.0~6.0 | 17.0~19.00 | ≤0.060 | N 0.20~0.3 | |

| DS205 | ≤0.15 | ≤1.0 | 18.0~19.00 | ≤0.030 | ≤0.030 | 2.00~3.00 | 17.00~18.00 | N 0.3~0.4 | ||

* slightly magnetic property occurred after cold-working.